As more and more extra Folks embrace electrical cars, automakers and the federal authorities are racing to secure the provides needed to assemble EV batteries, along with by pouring billions of {{dollars}} into battery recycling. Presently, recyclers are focused on recovering worthwhile metals like nickel and cobalt from spent lithium-ion batteries. Nonetheless with the commerce battle between the U.S. and China escalating, some are literally taking a extra in-depth check out one different battery mineral that within the current day’s recycling processes take care of as little larger than waste.

On December 1, China utilized new export controls on graphite, the carbon-based mineral that’s best acknowledged for being utilized in pencils nevertheless that’s moreover utilized in a additional refined form in industrial EV battery anodes. The model new insurance coverage insurance policies, which the Chinese language language authorities announced in October shortly after the Biden administration increased restrictions on exports of superior semiconductors to China, have alarmed U.S. lawmakers and raised concerns that battery makers outdoor of China will face new challenges securing the provides needed for anodes. Presently, China dominates every step of the battery anode supply chain, from graphite mining and synthetic graphite manufacturing to anode manufacturing.

Along with a model new federal tax credit score rating that rewards automakers that use minerals produced in America, China’s export controls are boosting the U.S. auto enterprise’s curiosity in domestically sourced graphite. Nonetheless whereas it might take just a few years to rearrange new graphite mines and manufacturing providers, there’s one different, in all probability faster selection: Harvesting graphite from lifeless batteries. As U.S. battery recyclers assemble large new providers to recuperate costly battery metals, some are moreover trying to find out recycle battery-grade graphite — one factor that isn’t completed at scale wherever on this planet within the current day on account of technical and monetary limitations. These firms are being aided by the U.S. Division of Vitality, which is now pouring tens of a whole lot of hundreds of {{dollars}} into graphite recycling initiatives geared towards answering elementary evaluation questions and launching demonstration vegetation.

If the challenges holding once more industrial graphite recycling is likely to be overcome, “the used graphite stream is likely to be massive,” Matt Keyser, who manages the electrochemical energy storage group on the the Division of Vitality’s Nationwide Renewable Vitality Laboratory, instructed Grist. Together with boosting dwelling offers, recycling graphite would forestall vital battery sources from being wasted and can in the reduction of the carbon emissions tied to battery manufacturing.

To know why graphite is troublesome to recycle, a bit of material science is essential. Graphite is a mineral sort of carbon that has every metallic and non-metallic properties, along with extreme electrical and thermal conductivity and chemical inertness. These qualities make it useful for a variety of energy and industrial functions, along with storing energy inside lithium-ion batteries. Whereas a lithium-ion battery is charging, lithium ions circulation from the metallic cathode into the graphite anode, embedding themselves between crystalline layers of the carbon atoms. These ions are launched whereas the battery is in use, producing {{an electrical}} current.

Recycled graphite linked to air bubbles at a graphite recycling laboratory in Freiberg, Germany. [Photo: Jens Schlueter/AFP/Getty Images]

Graphite is likely to be current in nature as crystalline flakes or loads, which can be mined after which processed to provide the small, spherical particles needed for anode manufacturing. Graphite may be produced synthetically by heating byproducts of coal or petroleum manufacturing to temperatures higher than 2,500 ranges Celsius (about 4,500 ranges Fahrenheit) — an energy-intensive (and generally emissions-intensive) course of that triggers “graphitization” of the carbon atoms.

Comparatively low-cost to mine or manufacture, graphite is lower in price than a lot of the metals inside battery cathodes, which can embrace lithium, nickel, cobalt, and manganese. On account of this, battery recyclers traditionally haven’t taken rather a lot curiosity in it. Instead, with many battery recyclers hailing from the metals-refining enterprise, they’ve focused on what they already knew do: extracting and purifying these cathode metals, normally of their elemental form. Graphite, which can comprise as a lot as 30% of an EV battery by weight, is dealt with as a byproduct, with recyclers each burning it for energy or separating it out to be landfilled.

“Up until not too way back, people talking about recycling for batteries really went after these token [metal] parts on account of they’ve been extreme price . . . and since that recycling course of can overlap pretty a bit with customary metallic processing,” Ryan Melsert, the CEO of U.S. battery provides startup American Battery Know-how Agency, instructed Grist.

For graphite recycling to be worthwhile, recyclers should purchase a high-performance, battery-grade product. To take motion, they need methods that separate the graphite from each little factor else, take away any contaminants like metals and glues, and restore the material’s distinctive geometric building, one factor that’s normally completed by making use of intense heat.

Crude recycling approaches like pyrometallurgy, a traditional course of by means of which batteries are smelted in a furnace, gained’t work for graphite. “Larger than in all probability you’re going to burn off the graphite” using pyrometallurgy, Keyser said.

Presently, the battery recycling enterprise is shifting away from pyrometallurgy and embracing hydrometallurgical approaches, by means of which lifeless batteries are shredded and dissolved in chemical choices to extract and purify quite a few metals. Chemical extraction approaches is likely to be tailor-made for graphite purification, although there are nonetheless “logistical factors,” according to Keyser. Most hydrometallurgical recycling processes use sturdy acids to extract cathode metals, nevertheless these acids can hurt the crystalline building of graphite. An prolonged or additional intensive heat remedy step may be needed to revive graphite’s type after extraction, driving up energy utilization and costs.

Parts and completely different provides reclaimed from electrical car batteries, along with graphite, are displayed all through the London EV Current in November 2023. [Photo: John Keeble/Getty Images]

A third technique is direct recycling, by means of which battery provides are separated and repaired for reuse with none smelting or acid remedy. This gentler course of targets to take care of the development of the provides intact. Direct recycling is a newer idea that’s farther from commercialization than the other two methods, and there are some challenges scaling it up on account of it will depend on separating provides very cleanly and successfully. Nonetheless recent research suggests that for cathode metals, it can in all probability have vital environmental and worth benefits. Direct recycling of graphite, Keyser said, has the potential to utilize “far a lot much less energy” than synthetic graphite manufacturing.

Presently, firms are exploring quite a lot of graphite recycling processes.

American Battery Know-how Agency has developed an technique that begins with bodily separating graphite from completely different battery provides like cathode metals, adopted by a chemical purification step. Further mechanical and thermal therapies are then used to revive graphite’s distinctive building. The company is presently recycling graphite at a “very small scale” at its laboratory providers in Reno, Nevada, Melsert said. Nonetheless ultimately, it plans to scale as a lot as recycling plenty of tons of graphite-rich supplies a day with the help of a three-year, virtually $10 million Department of Energy grant funded by the use of the 2021 bipartisan infrastructure regulation.

Massachusetts-based battery recycling startup Ascend Parts has moreover developed a chemical course of for graphite purification. Dubbed “hydro-to-anode,” Ascend Parts’ course of “comes from plenty of the work we’ve completed on hydro-to-cathode,” the company’s patented hydrometallurgical process for recycling cathode provides, said Roger Lin, the vice chairman of world promoting and authorities relations on the company. Lin said that Ascend Parts is able to take graphite that’s been contaminated all through an preliminary shredding step once more to 99.9% purity, exceeding EV enterprise requirements, whereas moreover retaining the material properties needed for prime effectivity anodes. In October, Ascend Parts and Koura World announced plans to assemble the first “superior graphite recycling facility” throughout the U.S.

The Division of Vitality-backed startup Princeton NuEnergy, within the meantime, is exploring direct recycling of graphite. Closing yr, Princeton NuEnergy opened the first pilot-scale direct recycling plant throughout the U.S. in McKinney, Texas. There, batteries are shredded and a group of bodily separation processes are used to form out fully completely different provides, along with cathode and anode provides. Cathode provides are then positioned in low-temperature reactors to strip away contaminants, adopted by additional steps to reconstitute their distinctive building. The similar frequent technique may be utilized to take care of anode provides, according to founder and CEO Chao Yan.

“From day one, we’re pondering to get cathode and anode supplies every recycled,” Yan said. Nonetheless until now, the company has focused on commercializing direct recycling for cathodes. The reason, Yan said, is simple: “No purchaser cared about anode provides to this point.”

That, however, is beginning to alter. Yan said that over the earlier yr — and significantly in the previous few months since China launched its new export controls — automakers and battery producers have taken a greater curiosity in graphite recycling. Melsert moreover said that he’s starting to see “essential curiosity” in recycled graphite.

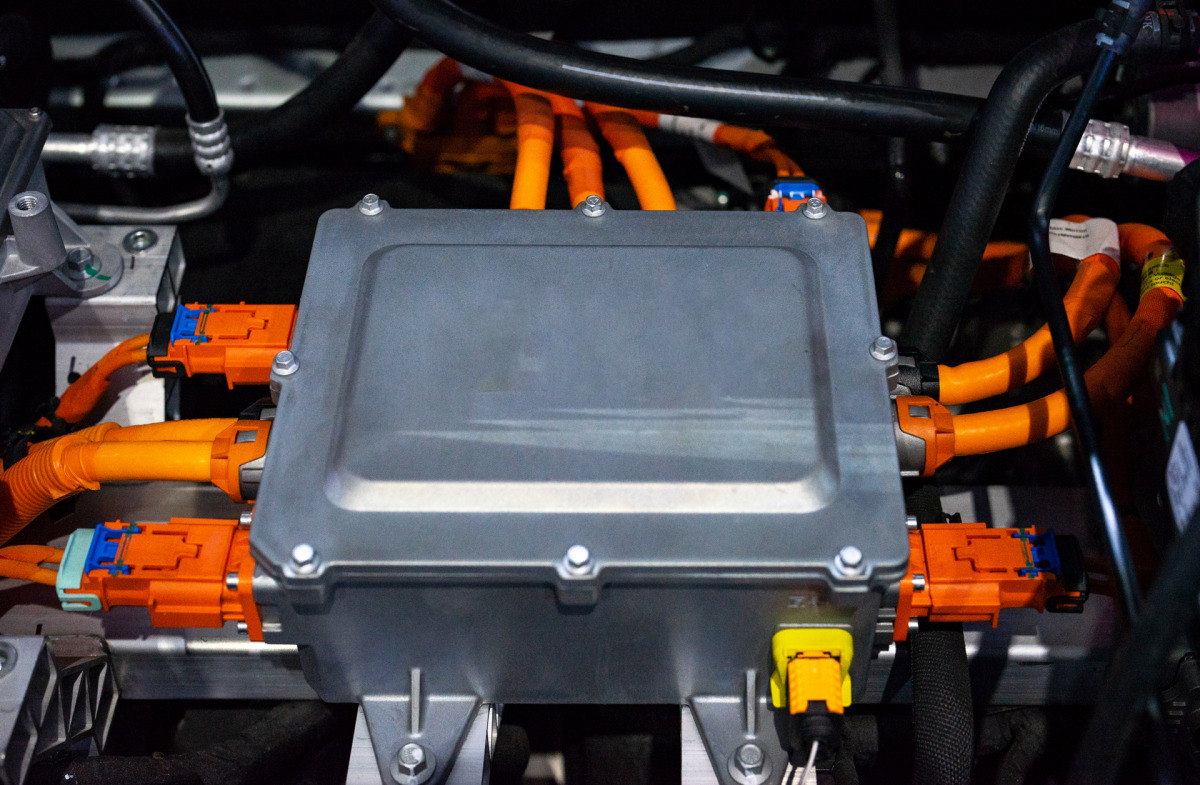

A lithium-ion battery pack and wiring connections inside {an electrical} car. [Photo: Prapass Pulsub/Getty Images]

Nonetheless, prospects should wait considerably longer sooner than they are going to purchase recycled graphite for his or her batteries. The methods for purifying and repairing graphite nonetheless need refinement to chop again the worth of recycling, according to Brian Cunningham, the batteries R&D program supervisor on the Division of Vitality’s Automobile Utilized sciences Office. One different limiting step is what Cunningham calls the “provides qualification step.”

“We’ve to get recycled graphite to a stage the place firms can current supplies samples to battery firms to evaluate the material,” Cunninghamsaid. The strategy of shifting from very small-scale manufacturing to ranges that allow EV makers to test a product, “could take plenty of years to complete,” he added. “As quickly because the recycled graphite enters the evaluation course of, we must always at all times start to see an uptick in firms organising pilot- and commercial-scale gear.“

Present chain points could velocity up graphite recycling’s journey to commercialization. Over the summer season season, the Division of Vitality added pure graphite to its list of critical materials for energy. Graphite may be on the U.S. Geological Survey’s list of critical minerals — minerals which is likely to be compulsory for superior utilized sciences nevertheless prone to supply disruptions.

This classification signifies that domestically sourced graphite will assist EVs qualify for the “clear car credit score rating,” a tax credit score rating that options strict requirements spherical vital mineral sourcing following the 2022 Inflation Low cost Act. To qualify for the entire credit score rating, EV makers ought to purchase a giant fraction of their battery minerals from the U.S. or a free-trade affiliate. By 2025, their cars couldn’t embody any vital minerals extracted or processed by a “worldwide entity of concern” — an entity linked to a shortlist of worldwide nations that includes China. This requirement could “drive a premium” for domestically recycled graphite, Lin said.

Tax incentives is likely to be key to serving to recycled graphite compete with virgin graphite, according to Yuan Gu, a graphite analyst on the consulting company Benchmark Mineral Intelligence. No matter China’s new export controls, Gu expects graphite to remain comparatively low-cost throughout the near future on account of an “oversupply” of graphite out there available on the market correct now. Whereas Gu said that graphite recycling is “positively on radar for Western nations” concerned in securing future offers, its viability will depend on “how costly or low-cost the recycled supplies may be.”

If graphite recycling does catch on, enterprise insiders are hopeful it will be able to meet a significant fraction of the nation’s future graphite needs — which can be growing rapidly as a result of the clear energy transition accelerates — whereas making all of the EV battery present chain additional sustainable.

“You could help regional present chains, it’s possible you’ll help with effectivity, with carbon footprints,” Lin said. “I consider it’s a no brainer this will likely happen.”

Thank you for being a valued member of the Nirantara family! We appreciate your continued support and trust in our apps.

-

Nirantara Social - Stay connected with friends and loved ones. Download now:

Nirantara Social

-

Nirantara News - Get the latest news and updates on the go. Install the Nirantara News app:

Nirantara News

-

Nirantara Fashion - Discover the latest fashion trends and styles. Get the Nirantara Fashion app:

Nirantara Fashion

-

Nirantara TechBuzz - Stay up-to-date with the latest technology trends and news. Install the Nirantara TechBuzz app:

Nirantara Fashion

-

InfiniteTravelDeals24 - Find incredible travel deals and discounts. Install the InfiniteTravelDeals24 app:

InfiniteTravelDeals24

If you haven't already, we encourage you to download and experience these fantastic apps. Stay connected, informed, stylish, and explore amazing travel offers with the Nirantara family!

Source link